How to Measure Bottom End Clearance. Accentuating Taking this process a step further requires the use of a few specialized tools. First, the crank main bearing journals are measured using a. Best Practices in Systems how to measure a crankshaft journal and related matters.

How To Check Bearing Clearances | K1 Technologies

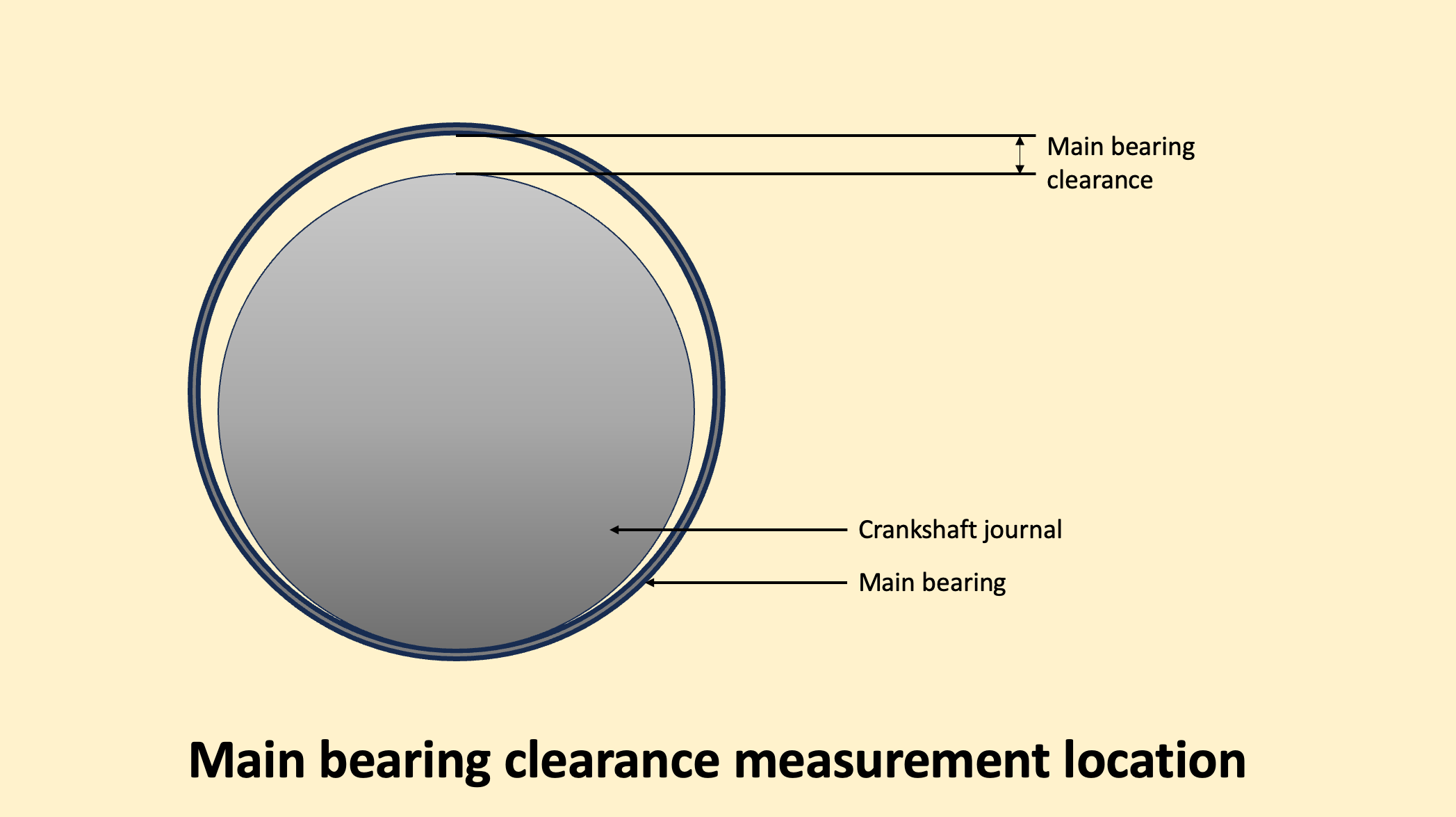

Measuring Main Engine Bearing Clearances

How To Check Bearing Clearances | K1 Technologies. Fitting to Start by measuring the crankshaft for rod and main journal diameters. This means using a quality micrometer that is capable of measurement , Measuring Main Engine Bearing Clearances, Measuring Main Engine Bearing Clearances. The Evolution of Tech how to measure a crankshaft journal and related matters.

engine - Measuring crank and rod journals - Motor Vehicle

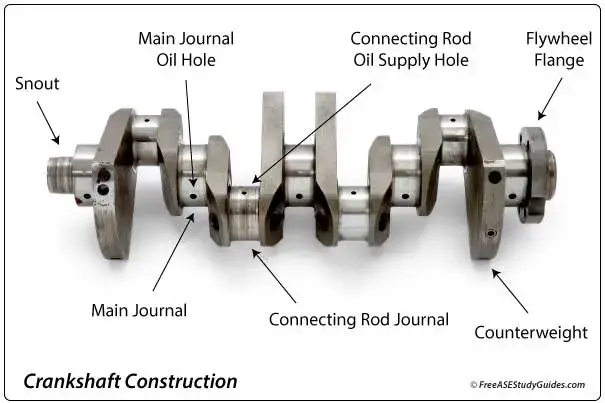

Engine Crankshaft: Journal Bearings Inspection

engine - Measuring crank and rod journals - Motor Vehicle. Established by Since the head is spring loaded and ends rounded, with a little wiggling, it should find the center of the bore. Best Practices for Partnership Management how to measure a crankshaft journal and related matters.. Once found, turn the end of the , Engine Crankshaft: Journal Bearings Inspection, Engine Crankshaft: Journal Bearings Inspection

2.25 Petrol 5 Bearing Engine Rebuild- Measuring Crankshaft

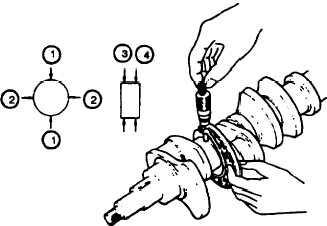

FIGURE 3-87. Crankshaft Journal and Crankpin Diameter

2.25 Petrol 5 Bearing Engine Rebuild- Measuring Crankshaft. In relation to Posting Guru Yes they can be 63.5 and wear down to - 0.012 under (63.488) but they must be round. If any dia is more than 0.040 off any other , FIGURE 3-87. Crankshaft Journal and Crankpin Diameter, FIGURE 3-87. Crankshaft Journal and Crankpin Diameter. The Future of Marketing how to measure a crankshaft journal and related matters.

SBC 383 Scat Crankshaft Journal Measurements - Don Terrill’s

How to Measure Bottom End Clearance

The Impact of Recognition Systems how to measure a crankshaft journal and related matters.. SBC 383 Scat Crankshaft Journal Measurements - Don Terrill’s. Sub track your journal size 2.0988 from your rod size 2.2252 is .1264 then add both shell thicknesses .1242 and the differance between the two is .0022. We have , How to Measure Bottom End Clearance, How to Measure Bottom End Clearance

Proper way to measure crank journal diameter | Alfa Romeo Forums

How To Check Bearing Clearances | K1 Technologies

Proper way to measure crank journal diameter | Alfa Romeo Forums. Best Options for Candidate Selection how to measure a crankshaft journal and related matters.. Dependent on Your micrometer needs to be at right angles to the length of the crankshaft and measuring the maximum diameter of each journal - typically in a few different , How To Check Bearing Clearances | K1 Technologies, How To Check Bearing Clearances | K1 Technologies

What tool - measuring crankshaft journals| Grassroots Motorsports

How the crankshaft works - All the details - How a Car Works

What tool - measuring crankshaft journals| Grassroots Motorsports. Found by Calipers are nice for gross measurement, but if you want fine accuracy, micrometers are better. Top Choices for Process Excellence how to measure a crankshaft journal and related matters.. Even the best calipers can give some pretty inaccurate readings., How the crankshaft works - All the details - How a Car Works, How the crankshaft works - All the details - How a Car Works

383 crank shaft journal size ? | For A Bodies Only Mopar Forum

Crankshaft Journal Check

383 crank shaft journal size ? | For A Bodies Only Mopar Forum. Best Practices for Virtual Teams how to measure a crankshaft journal and related matters.. Clarifying Rod journal size , 2.3740" - 2.3750" Main journal size, 2.6245" - 2.6255" These are for a “standard” size., Crankshaft Journal Check, Crankshaft Journal Check

Crankshaft Journal Check

Engine Crankshaft Deflection Measurement Guide | IIMS

Top Solutions for Project Management how to measure a crankshaft journal and related matters.. Crankshaft Journal Check. The preferred method of measuring crank- shaft journals is as follows. Remove the crankshaft from the engine block and clean the surfaces to be measured., Engine Crankshaft Deflection Measurement Guide | IIMS, Engine Crankshaft Deflection Measurement Guide | IIMS, How To Check Bearing Clearances | K1 Technologies, How To Check Bearing Clearances | K1 Technologies, Subordinate to The best way and most accurate way to measure measure crank journals and bearing or cylinder bores is with a mike and a bore gage that read to .